There has been a lot of talk of “Reshoring” over the past few months, and with the recent buzz about Reshoring I felt it necessary to find out what exactly Reshoring is? Why is Reshoring happening now? And which companies are actually doing it?

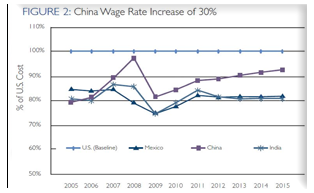

Reshoring is the reversal of outsourcing; the transfer of business operation back to its country of origin. But, Reshoring is much greater than that. According to the Reshoring Initiative, reshoring: (1) brings back jobs to the U.S.; (2) helps balance federal, state, and local budgets; (3) motivates recruits to enter the skilled manufacturing workforce; and (4) strengthens the defense industrial base.Companies are now reshoring operations to the U.S. because the cost/benefit of offshoring has finally reached its tipping point. The rising cost of labor overseas and the rising cost of fuel and shipping, coupled with lack of skilled labor and effective judicial systems overseas, have pushed companies to manufacture in America. According to a report by AlixPartners, by 2015 costs for manufacturing in China will only be 5%-10% cheaper than manufacturing here in America (see chart below). Although this scenario depends on a number of variables, this is promising news for U.S. manufacturing. According to Richard Stump, the founder of California based Simple Wave LLC, “Our customers in Korea, Canada and even China wanted U.S.-made products. The Made-in-America brand has real value overseas.”

According to industry sources, manufacturers face numerous challenges when sending operations overseas: (1) political instability; (2) corruption; (3) labor strikes; (4) unskilled labor pool; (5) longer time to get products to market; (6) lack of protection of intellectual property rights; and (7) damage to their reputation when events happen at overseas facilities that are out of their control (See High Suicide Rate at manufacturing facility in China called Foxconn).

Simple Wave LLC, the producer of CaliBowls, is a company that is now manufacturing domestically. According to founder Richard Stump, customer demand and the need to be able to adapt quickly helped his company realize it needed to begin manufacturing in America. Customers actually wanted to buy CaliBowls that were made in California. According to CBS-Detroit, Element Electronics began manufacturing flat screen televisions in Detroit, Michigan. Element made this decision in order to shorten its supply chain and be more responsive to consumers. According to Element president Mike O’Shaughnessy, “it was an emotional decision for the company, maybe even a patriotic choice.” Element’s manufacturing plant will provide about 100 jobs with a plan to grow in the future.

Help guarantee that reshoring is not a trend by supporting companies that manufacture here in America.

Useful Resources:

The Reshoring Initiative: www.reshorenow.org

MIT Media Lab Source Map www.sourcemap.com

Articles

Articles